AceCannon

Active Member

Just to play devil's advocate, I contend that both the distribution hub and the branch hub are wasted in this setup.

I believe the sole purpose of the distribution hub is to land wires in its punch down blocks. The hub's job is to land wires and amplify signals and provide a "new" 500 foot wiring limit. You aren't landing any wires on the distro hub or the branch hub, and since all your lights are wired to the hub, you are using its 500 foot limit, but not the 500 foot limit of the branch itself. Perhaps it would make more sense for the first 66 block segment to attach directly to the branch, and the second segment to connect to the hub.

Heck if you paid for the distro hub and branch, why not just land your connections on it? I'll bet you could put all the connections from your 66 block onto the two ALC devices instead. Is there some downside to wiring the way ALC intended (i.e. landing to their punchdowns)? (Devil's advocate -- no criticism intended)

--Bob

P.S. I just finished the wiring layout for my house. It contains 11 Hubs in 4 locations for 97 switches and 59 AUXes. To get around the 500'/branch limit I need lots of hubs! The 66blk is $12/12loads (assuming several AUXes). The hub is $40/9 loads (and 10 AUXes) so it is a bit more expensive.

1. I think you are pretty much spot-on, at least as my setup is at present. (except note that each of the two rooms is terminated to a separate punch down on the branch hub - all the loads do not go to a single punch down.)

2. The only reason I picked up the distribution hub was for the rj45 jack. The controller comes with the rj45 socket cable designed to connect with a cat5e cable. Silly, perhaps, but true. $26.00, and the plan is to land future branch hubs to it.

3. My plan for ALC has been to start with these two rooms, then expand as time and economics allow. So, tentatively, I will add 66 blocks and connect each room's switches (collectively) to a single, unique spot on the branch hubs. I wanted the amplification of the branch hub and the trouble shooting of the enhanced hub's DIP switches. I figure it isn't likely a single room's switches will exceed the 500ft limit. But there is NO question that my eventual installation will exceed it. Clearly there are multiple ways to do this successfully, however.

No offense taken at all. I appreciate the analysis and healthy repartee.

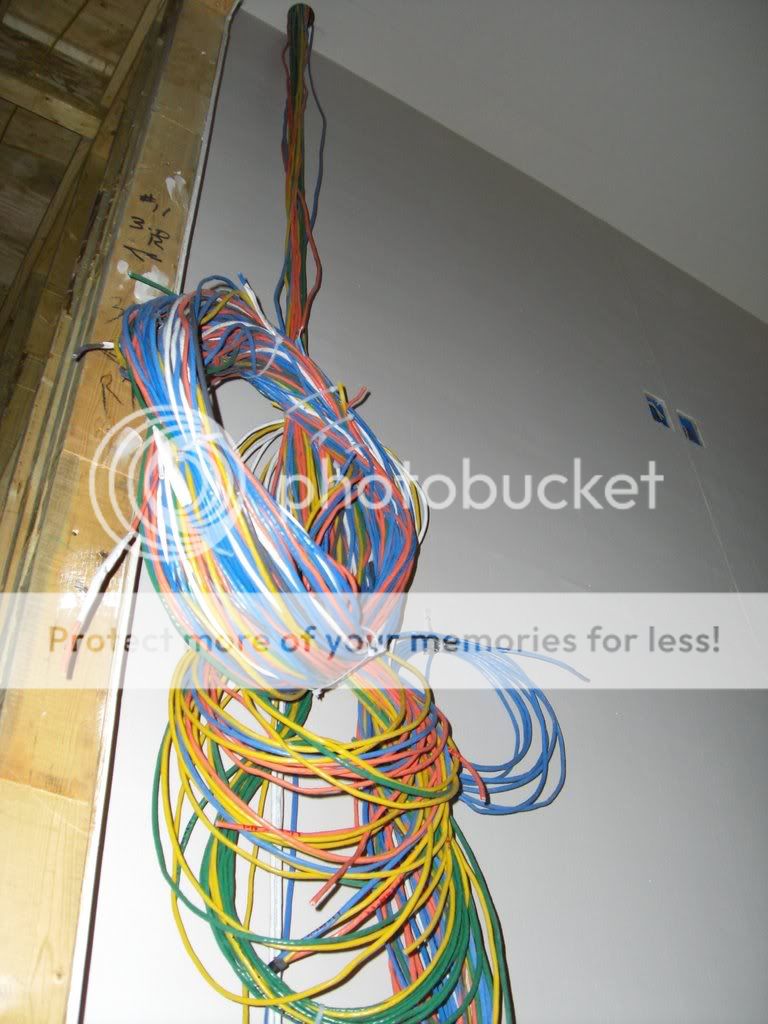

Pic: ugly mess of a portion of the as-yet unused cat5e going to every gangbox in the house for future ALC. There is another big wad coming out of the floor.